Coal combustion products (CCPs) are materials produced when we burn coal to produce electricity. These materials are comprised of fly ash, flue gas desulfurization (FGD) materials, bottom ash, boiler slag and other power plant by-products. While approximately 41 percent were used beneficially, the rest were disposed. The potential for use is exceptional and the environmental benefits significant. CCP use conserves natural resources as the need to extract virgin materials is eliminated. Millions of acres of land otherwise used for disposal are preserved by using CCPs. Substituting one ton of fly ash for one ton of Portland cement eliminates one ton of CO2 otherwise released during cement production.

Applications span an infinite variety of possibilities in the architecture, engineering and construction industries as well as in manufacturing. The number of applications is limited largely by imagination. CCPs are categorized in four groups, each based on physical and chemical forms derived from coal combustion methods and emission controls:

Flue gas desulfurization (FGD) materials are produced by chemical “scrubber” emission control systems that remove sulfur and oxides from power plant flue gas streams. Residues vary, but the most common are FGD gypsum (or “synthetic” gypsum) and spray dryer absorbents. FGD gypsum is used in almost thirty percent of the gypsum panel products manufactured in the U.S. It is also used in agricultural applications to treat undesirable soil conditions and to improve crop performance. Other FGD materials are used in mining and land reclamation activities.

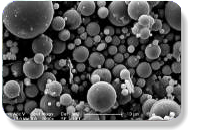

Fly ash is most commonly used as a high-performance substitute for portland cement or as clinker for portland cement production. Cements blended with fly ash are becoming more common. Building material applications range from grouts and masonry products to cellular concrete. Many asphaltic concrete pavements contain fly ash. Geotechnical applications include soil stabilization, road base, structural fill, embankments and mine reclamation. Fly ash also serves as filler in wood and plastic products, paints and metal castings.

Bottom ash and boiler slag can be used as a raw feed for manufacturing portland cement clinker, as well as for skid control on icy roads. These materials are also suitable for geotechnical applications such as structural fills and land reclamation. The physical characteristics of bottom ash and boiler slag lend themselves as replacements for aggregate in flowable fill and in concrete masonry products. Boiler slag is also used for roofing granules and as blasting grit.

Because there are many boilers and combustion processes, it is not possible to use a few terms to describe CCPs. In fact, it is clear that depending on geographic location, company, sector of the industry, regulatory perspective, etc., terms are often used interchangeably or even incorrectly. The glossary is an attempt to define the most commonly used terms pertaining to production, handling and use of CCPs and, when needed, to the disposal of coal combustion by-products (CCBs) - see menu above.